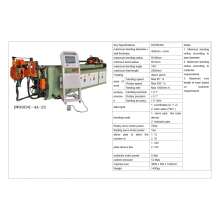

WAW-600D hydraulic pipe bending machine

| Payment Type: | L/C,T/T |

|---|---|

| Terms of Trade: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 7 Days |

| Packaging: | Export Wooden Case |

|---|---|

| Productivity: | 300 Sets/month |

| Brand: | Chenda |

| Transportation: | Ocean |

| Place of Origin: | China |

| Supply Ability: | 300 Sets/month |

| Certificate: | CE SGS |

| HS Code: | 9024101000 |

| Port: | QINGDAO |

Basic Info

Model No.: WAW-600D

Click on the follow link to find out more information: https://www.jncdtester.com/computer-control-servo-hydraulic-universal-testing-machine/

Company Info

- Company Name: Jinan Chenda Testing Machine Manufacturing Co., Ltd.

- Representative: Liu Peng

- Product/Service: universal testing machine , compression testing machine , Friction And Wear Testing Machine , impact testing machine , torsion testing machine , tensile testing machine

- Capital (Million US $): 10000000 RMB

- Year Established: 2010

- Total Annual Sales Volume (Million US $): Below US$1 Million

- Export Percentage: 31% - 40%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 6

- No. of R&D Staff: Fewer than 5 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): Below 1,000 square meters

- Factory Location: NO.687 SONGZHUANG INDUSTRIAL PARK JINAN CITY SHANDONG CHINA

- Contact Person: Ms. Anny Yuan

- Tel: 86-531-61311368

Email to this supplier

Premium Related Products

Other Products

Hot Products

advanced oem customized perfect quality aluminium alloy castingsperfect quality oem service chinese promotional aluminium alloy die casting partaluminium alloy high quality aluminium gravity die castingfactory price durable perfect quality gravity mould castingNozzle part oem service alloy high quality custom castingWholesale OEM Service High Precision Custom Aluminum Die Casting DieMachinery Equipment Parts Precision Aluminum Die Castingsperfect quality alloy high quality aluminium casting partsIntake manifold Trade Assurance Custom Made In China Intake manifold CastingProfessionl Factory Made T6 Heat treatment Aluminium Gravity Die Castingchina oem professional manufacturer high precision aluminum castinghigh precision durable oem service a413 aluminum die castingHigh Precision Medical spare parts Promotional Die CastingFactory Price Wholesale Precision CNC Machining Precise Die Casting PartsProfessional Manufacturer China High Quality Gravity Casting Productsperfect quality service chinese promotional oem casting heavy equipment part